AI Vision Platform

Automatically DETECTING defects

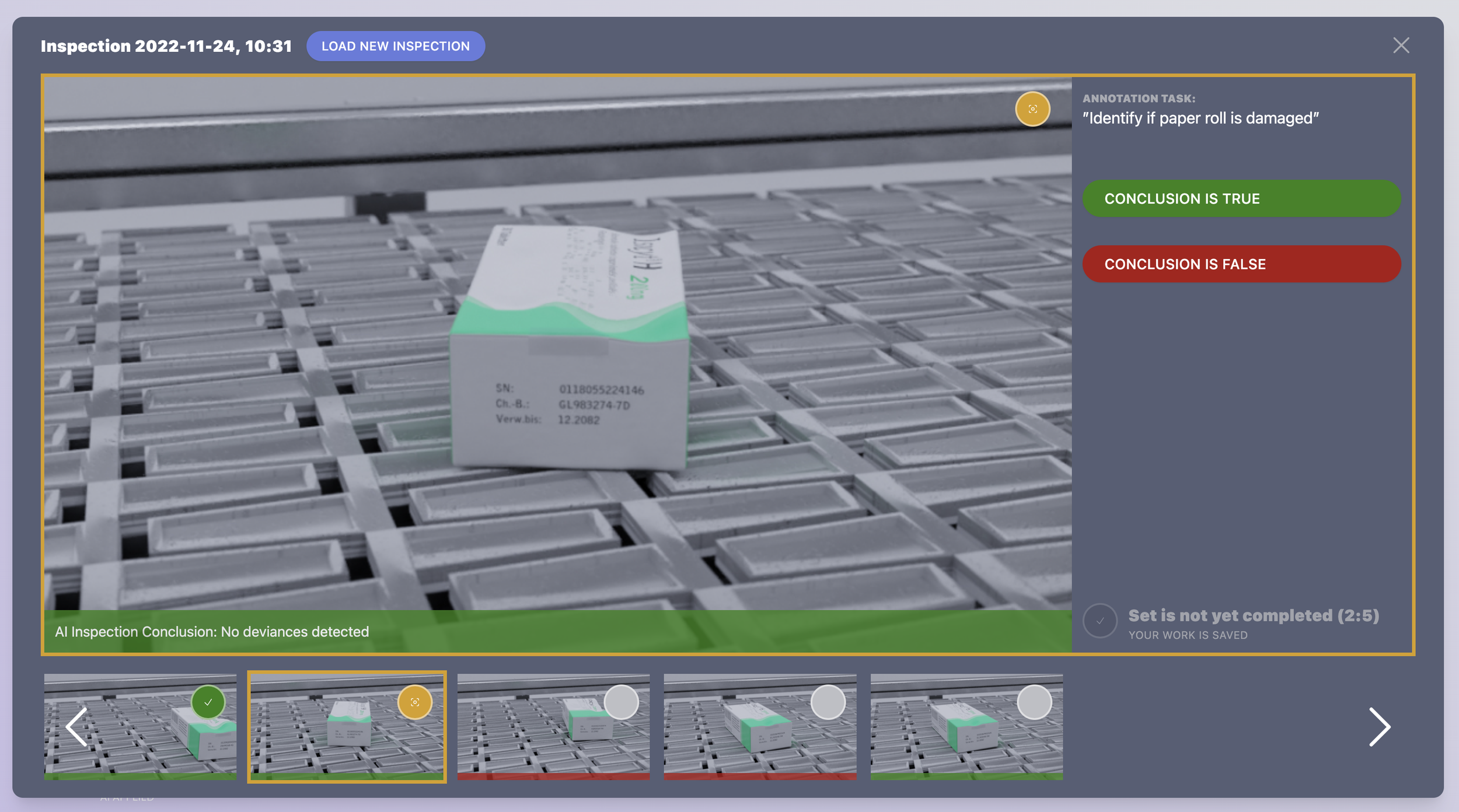

Our AI Vision Platform combines cutting edge machine learning with a solid infrastructure for computation, training, storage and annotation.

Customer-unique machine learning models can be trained to discover different kinds of quality issues or anomalies in real time.

This means manual inspection can be fully or partly replaced by an automated solution.

Improving quality and also enabeling traceability gives you better control of your customer deliveries. Reducing the number of defects also means less waste and improved customer satisfaction.

When combining data from the quality inspection solution with data from other data sources in the production system you will gain new insights about root-causes and you can work proactively with improving the manufacturing process further.

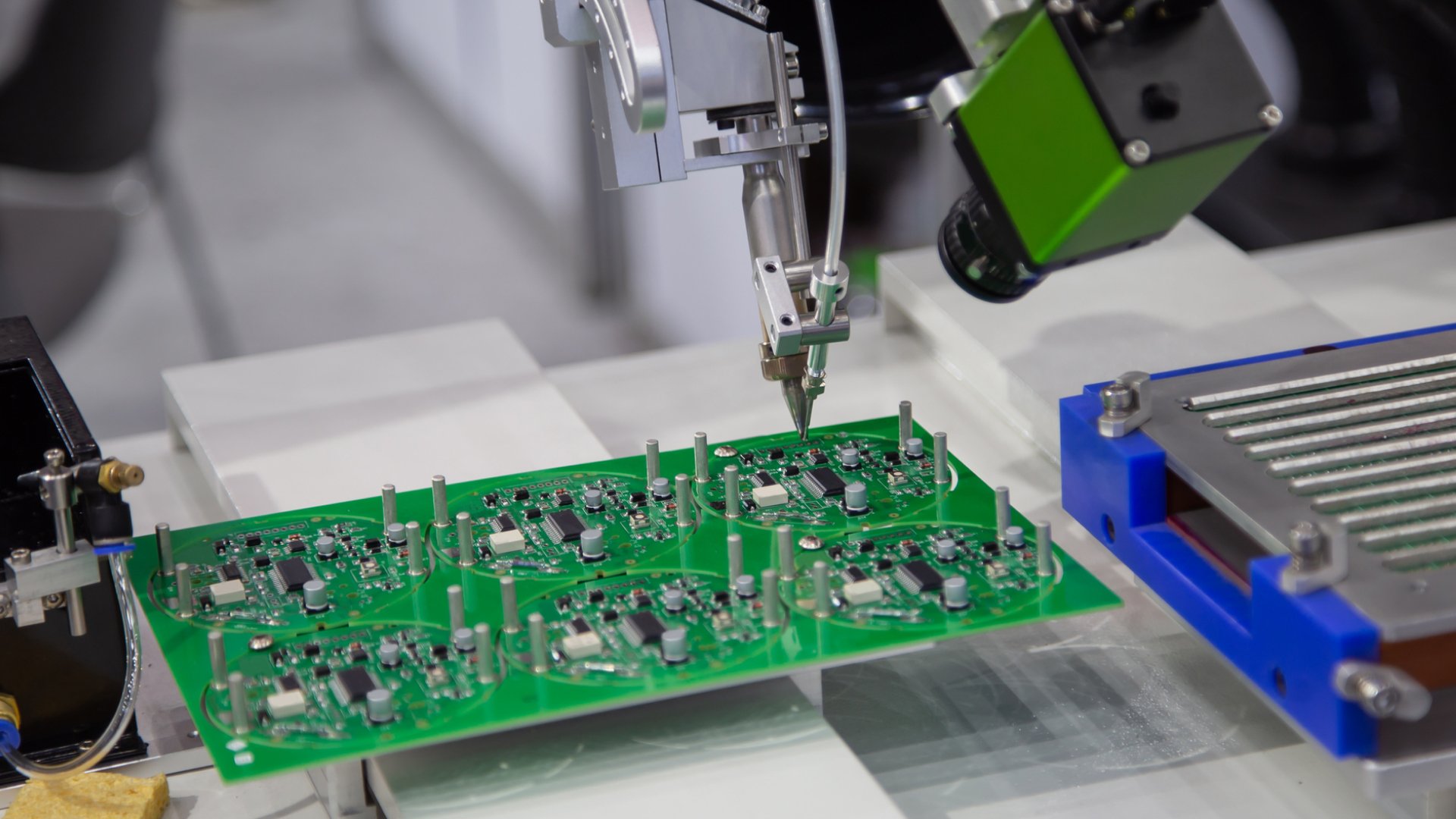

Neurolearn is partnering with hardware experts (camera, robot etc.) and system integrators to be able to deliver a complete customer solution which is state of the art.

With the Neurolearn platform you’ll have a fully integrated solution which is customized and optimised for your specific application. The AI system will learn over time and improve and it can also be re-trained in case you change anything in your product.

Our system solution is fast, meaning you can inspect many products per time unit. You will also receive a solution for data storage and traceability which gives you opportunities to analyse the data for additional insights.

The system is also easy to scale if you’d like to add new detections and additional sensors.

Does manual inspection

still make sense?

Possible Defects:

Assembly errors

Cracks

Cavities

Contamination

Damages

Flaws in soldering joints

Fractures

Grain quality

Scratches

Textual errors

Our AI Vision Platform can be trained to detect different defects and anomalies in realtime. Increased customer satisfaction as well as insights in root-causes improves will increase you internal and external effectiveness.

Neurolearn Vision Platform is a plug-and-play solution for automized visual quality inspection.

Many steps in the production process would benefit from removing defects so that the product is not refined further wasting money and time.

With new, modern technologies, automation is now possible also where it was not possible or profitable before.

Our Vision platform shortens the implementation time and reduces the capital investments which makes it easier to try out AI-driven quality inspections.

Neurolearn Vision Platform

Our delivery:

Cloud-based storage and training of the Machine Learning model.

The Machine Learning model can be deployed locally on premise when low latency is needed.

Choosing the most suitable camera-options depending on application performance demands, resolution and/or choosing other types of sensors.

Delivery and installation of hardware.

Configuration, training and commissioning.

On-demand retraining and upgrading of machine learning model

Low Latency INSTALLED On Prem

Cloud-BASED

The Machine Learning model can be deployed locally on premise when low latency is needed, when there are large data volumes or due to security reasons.